|

|

Computer use in high-dust environments

The importance of the ingress protection rating of computer equipment used in high-dust environments such as metal casting foundries to reliable operation, less downtime, and lower total cost of ownership.

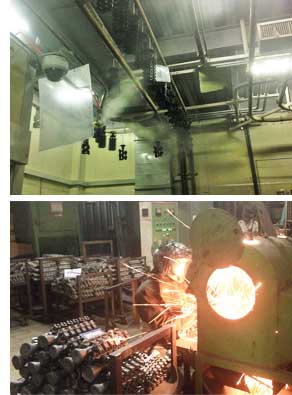

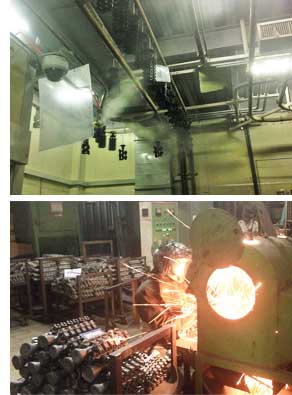

Every aspect of the modern worldwide economy relies on computers. Success (and failure) of virtually any business depends on reliable operation of computer, network and communication systems. What does that mean to industries where computers are used in extreme environments where dust and heat are part of the job? Environments like, for example, metalworking and casting in foundries (see picture below)? In this article we discuss the challenges of standard PCs in foundry and similar settings, and the benefits of using rugged tablet computing equipment instead.

Foundries is where things are made from molten metal. Unlike computer chip foundries where much of the operation is completely dust-free, metal foundries look more like something out of Dante's Inferno or images from the industrial revolution. There are furnaces with temperatures of up to 1,500 degrees Centigrade (2,730 degrees F) and more, molten metal, sanding, grinding, sparks, plenty of dust and shavings, sprinklers, condensation, and so on and so on. It's one of the harshest working environments imaginable — hard on humans and hard on the industrial robots and computers they use on the job.

Foundries, of course, come in different types and sizes, using different technologies. High-volume casting of metals such as zinc, copper, aluminum, lead, aluminum, magnesium, tin and their alloys use dies made of hardened steel. That's called die casting, and there are several other technologies that use permanent molds. Foundries, of course, come in different types and sizes, using different technologies. High-volume casting of metals such as zinc, copper, aluminum, lead, aluminum, magnesium, tin and their alloys use dies made of hardened steel. That's called die casting, and there are several other technologies that use permanent molds.

Not all casting, however, uses expensive permanent molds. There is a number of expendable mold technologies that use sand, plaster, clay, foam and other easily manipulated materials. Expendable molds are less expensive and sand molding, especially, accounts for a large percentage of all metal castings. Sand casting is very flexible in terms of the size of operation as well as the size of the metal parts cast. The term "expendable" is relative as the sand can be recycled.

Dust is the enemy

While all metal casting foundry operations are extreme environments, a special challenge with sand and other expendable mold casting foundries is the dust associated with sand, plaster, grinding, mixing and the overall preparation and handling of the expendable casts. Dust is ever-present, even with moisture sprayers and ventilation systems, and it gets everywhere and into everything.

This makes for a very demanding environment to reliably run the computer systems used for process and inventory control, asset management, quality control, throughput, scheduling and whatever else is required for the smooth and efficient running of the operation. Standard desktop computing equipment was never designed for this type of use and, as a result, often quickly fails, causing costly downtime and interruptions. The answer is ruggedized computing equipment designed to hold up in such environments.

The importance of the Ingress Protection rating

Ruggedized computing equipment must pass a series of stringent environmental and stress testing, and among them the Ingress Protection rating is especially important. The Ingress Protection rating, or IP, is defined and described in the IEC (International Electrotechnical Commission) 60529 international standard. It classifies how well electrical enclosures are protected against intrusion of solid objects, dust, and water. When used to rate the degree and effectiveness of sealing of a ruggedized computers (be it a handheld, a notebook or a tablet), the IP rating indicates how well a housing keeps out water, solids and dust.

For computing equipment used in dusty environments, the first numeral in the IP rating is the most important. If dust is an issue, ratings 0 through 4 means the equipment is entirely unsuitable. That's because a "3" rating only protects against solids over 2.5 mm in diameter (i.e. dust and even sand can get in), and even a "4" rating still only provides protection against solids with diameters larger than 1 mm. So a "4" rating offers no protection at all against dust or even fine and some medium sand. How about a "5" rating, the second highest? Still not good enough. The rating claims protection against dust, but qualifies that with "limited ingress permitted, no harmful deposit." Sorry, but that's not good enough in computers where any dust deposit can be harmful. So it's really only the top "6" rating that provides total protection against dust. For computing equipment used in dusty environments, the first numeral in the IP rating is the most important. If dust is an issue, ratings 0 through 4 means the equipment is entirely unsuitable. That's because a "3" rating only protects against solids over 2.5 mm in diameter (i.e. dust and even sand can get in), and even a "4" rating still only provides protection against solids with diameters larger than 1 mm. So a "4" rating offers no protection at all against dust or even fine and some medium sand. How about a "5" rating, the second highest? Still not good enough. The rating claims protection against dust, but qualifies that with "limited ingress permitted, no harmful deposit." Sorry, but that's not good enough in computers where any dust deposit can be harmful. So it's really only the top "6" rating that provides total protection against dust.

What about the second number in the IP rating system? It describes the protection against water and condensation. Here, a "0" means no protection at all (almost all standard computing equipment falls into this category), ratings 1 through 4 mean varying levels of protection against water spray, but even "4" still allows "limited ingress." A "5" means protection against low pressure water jets from all directions, and that certainly guards against dripping condensation and inadvertent exposure to water, even from hoses. Ratings beyond that guard against strong jets of water ("6"), short and shallow full immersion ("7"), and full long-term immersion.

What does that mean? Essentially that in dusty environments no standard, unrated desktop or laptop will last very long. That's because virtually all such standard equipment has cooling vents and other direct openings into the interior of the computer (such as drive bays, card slots and even the keyboard). Dust is present almost anywhere, though usually not in harmful quantities. Computers used in dusty and very dusty environments, however, should absolutely be sealed to IP6x specification. How about liquids? It depends on the environment and what sort of exposure to liquids is likely. It makes little sense to pay for protection against full immersion when none is ever likely. So for anything used indoors, even in harsh industrial settings, IPx5 is usually adequate. Anything less is not.

Rugged tablet computers such as the Samwell RUGGEDBOOK SR820 provide full Windows functionality and performance in a hardened, fanless compact form factor that can hold up even in metal casting and foundries. Measuring just 10.1 x 6.2 x 1.5 inches and weighing under three pounds, the SR820 is smaller and lighter than full-size rugged tablets without requiring many compromises. There is good wired connectivity on board, all the connectors are standard size, and there is a wealth of wireless functionality (including available GPS and 3.75G radio) and also an integrated camera and optional laser scanner. The device can easily be carried and just as easily mounted virtually anywhere in via standard VESA mounts (shown with RAM-Mount ball-and-socket mounting system). Rugged tablet computers such as the Samwell RUGGEDBOOK SR820 provide full Windows functionality and performance in a hardened, fanless compact form factor that can hold up even in metal casting and foundries. Measuring just 10.1 x 6.2 x 1.5 inches and weighing under three pounds, the SR820 is smaller and lighter than full-size rugged tablets without requiring many compromises. There is good wired connectivity on board, all the connectors are standard size, and there is a wealth of wireless functionality (including available GPS and 3.75G radio) and also an integrated camera and optional laser scanner. The device can easily be carried and just as easily mounted virtually anywhere in via standard VESA mounts (shown with RAM-Mount ball-and-socket mounting system).

Most importantly for use in high-dust environments such as casting foundries, the SR820's lack of a fan means superior sealing to keep out dust and other harmful particles. The device is easily cleaned and can also handle extreme operating temperatures up to 140 degrees Fahrenheit (60 degrees Centigrade). What that means in such environment is that compared to standard desktops and laptops, rugged tablet computers such as the Samwell RUGGEDBOOK SR820 can provide more reliable operation, less downtime, and lower total cost of ownership.

Relevant Information:

Samwell Group RUGGEDBOOK SR820 page

Rugged computing terminology and standards

Degrees of protection defined by IEC 60529

To learn more about the ruggedized Samwell SR820 tablet computer and its many applications, email RUGGEDBOOK at info@ruggedbook.com.tw. And check RuggedPCReview.com's full analysis of the SR820.

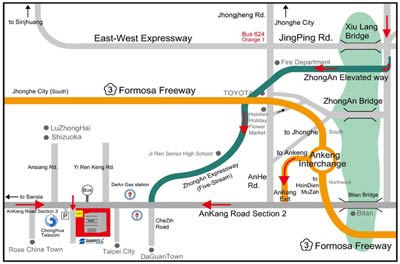

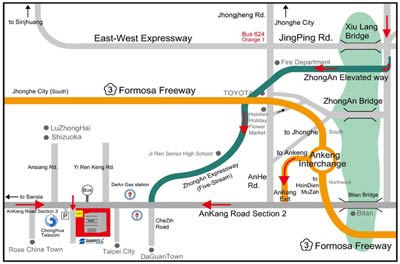

RUGGEDBOOK Headquarters

Samwell Building

317-1, Sec. 2,

AnKang Rd., Xindian Dist.

New Taipei City 23153, Taiwan (R.O.C.)

Telephone: 886-2-2214-1133

Fax: 886-2-2215-5458

Web: www.ruggedbook.com.tw

info@ruggedbook.com.tw

|

Foundries, of course, come in different types and sizes, using different technologies. High-volume casting of metals such as zinc, copper, aluminum, lead, aluminum, magnesium, tin and their alloys use dies made of hardened steel. That's called die casting, and there are several other technologies that use permanent molds.

Foundries, of course, come in different types and sizes, using different technologies. High-volume casting of metals such as zinc, copper, aluminum, lead, aluminum, magnesium, tin and their alloys use dies made of hardened steel. That's called die casting, and there are several other technologies that use permanent molds.

For computing equipment used in dusty environments, the first numeral in the IP rating is the most important. If dust is an issue, ratings 0 through 4 means the equipment is entirely unsuitable. That's because a "3" rating only protects against solids over 2.5 mm in diameter (i.e. dust and even sand can get in), and even a "4" rating still only provides protection against solids with diameters larger than 1 mm. So a "4" rating offers no protection at all against dust or even fine and some medium sand. How about a "5" rating, the second highest? Still not good enough. The rating claims protection against dust, but qualifies that with "limited ingress permitted, no harmful deposit." Sorry, but that's not good enough in computers where any dust deposit can be harmful. So it's really only the top "6" rating that provides total protection against dust.

For computing equipment used in dusty environments, the first numeral in the IP rating is the most important. If dust is an issue, ratings 0 through 4 means the equipment is entirely unsuitable. That's because a "3" rating only protects against solids over 2.5 mm in diameter (i.e. dust and even sand can get in), and even a "4" rating still only provides protection against solids with diameters larger than 1 mm. So a "4" rating offers no protection at all against dust or even fine and some medium sand. How about a "5" rating, the second highest? Still not good enough. The rating claims protection against dust, but qualifies that with "limited ingress permitted, no harmful deposit." Sorry, but that's not good enough in computers where any dust deposit can be harmful. So it's really only the top "6" rating that provides total protection against dust.

Rugged tablet computers such as the Samwell RUGGEDBOOK SR820 provide full Windows functionality and performance in a hardened, fanless compact form factor that can hold up even in metal casting and foundries. Measuring just 10.1 x 6.2 x 1.5 inches and weighing under three pounds, the SR820 is smaller and lighter than full-size rugged tablets without requiring many compromises. There is good wired connectivity on board, all the connectors are standard size, and there is a wealth of wireless functionality (including available GPS and 3.75G radio) and also an integrated camera and optional laser scanner. The device can easily be carried and just as easily mounted virtually anywhere in via standard VESA mounts (shown with

Rugged tablet computers such as the Samwell RUGGEDBOOK SR820 provide full Windows functionality and performance in a hardened, fanless compact form factor that can hold up even in metal casting and foundries. Measuring just 10.1 x 6.2 x 1.5 inches and weighing under three pounds, the SR820 is smaller and lighter than full-size rugged tablets without requiring many compromises. There is good wired connectivity on board, all the connectors are standard size, and there is a wealth of wireless functionality (including available GPS and 3.75G radio) and also an integrated camera and optional laser scanner. The device can easily be carried and just as easily mounted virtually anywhere in via standard VESA mounts (shown with